As bin collection days change again in Rye, what happens to all that waste is once more on people’s minds. Where the waste goes which cannot be recycled, and how it helps power homes, was the focus for the annual professional development event and AGM of the southeast branch of the Emergency Planning Society.

As a Fellow of this national body for emergency planning professionals and leader of Rye Emergency Action Community Team (React), I took part in the event, joining 14 other members who met at Veolia’s £160m Energy Recovery Facility (ERF) at Newhaven. We were shown round by Veolia’s Paul McMullen and Phil Preece.

Opened in 2011, the state of the art facility looks like a silver submarine, dominates the industrial area of Newhaven despite half the plant being below ground and is part of an integrated waste management (IWM) system which collects, separates, recovers, and composts general waste in 14 facilities across East Sussex, Brighton and Hove. This IWM produces around 400k tonnes of waste each year which in the past went to landfill but, by processing, this figure is now much reduced.

In 2014, the Newhaven ERF received around 250k tonnes of residual general waste from five transfer stations within the East Sussex, Brighton and Hove area and, once the ERF has burnt this waste for the generation of electricity, only a small percentage is left to go back to landfill and they hope this quantity can be reduced to 5% within 10 years. Some of the generated electricity is taken for local power and the remainder goes to the National Grid. Typically at 400MWper day this provides enough for about 25,000 homes. Power generation from waste now accounts for 1.5% of the UK’s electricity supply but by 2020 it is intended that it will be 6% of total, making a significant contribution to the country’s energy security.

McMullen gave a very full explanation of the plant’s operation which, apart from a short period of annual closure for boiler and other maintenance, runs year-round 24/7. There was a full discussion of the business continuity and emergency plans for the facility and the latter are designed to handle risks such as fire, localised flooding and other industrial incidents. A centralised control monitors all operations and the security of the site and a tour of the plant revealed the high levels of health and safety and environmental controls in place.

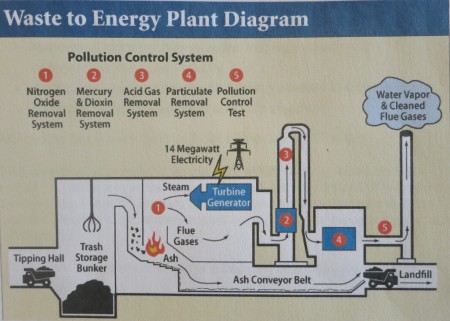

The main elements of the ERF process, and the pollution control system, are shown in the diagram:

- Rubbish from households, local authority services and some local businesses is brought to the ERF, where it is tipped into the storage bunker and from the bunker, the rubbish is lifted automatically onto a feed hopper by an overhead crane; the hopper then feeds the rubbish into twin incineration units where it is burned at temperatures in excess of 850 degrees centigrade.

- Oil fired burners aid startup and closure and also provide the ability to maintain a correct temperature in the incinerator, which superheats steam to drive the turbine, generating electricity for the National Grid. The gas is processed to remove particulates (dust) and reduce noxious gases and pollutants. Water vapour and cleaned gas is released through the 65m high chimneys, with the gases constantly monitored to ensure they meet strict environmental regulations and legislation.

- Ash from the incineration process goes into a bunker and, after the removal of metals, this is recycled into aggregate for the construction and road industry; while particulates removed from the filtering process are taken to a separate plant for treatment and safe disposal.

All this helps to transform waste into a resource and to reduce the amount going into landfill sites. Recent new regulations have placed a duty on waste collectors to separately collect recyclates in order to achieve a higher rate of recycling. The Veolia Newhaven ERF plays a key part in the integrated waste handling system of the southeast.