In May, the Rother Environmental Group (REG) visited the Materials Reclamation Facility (MRF) in Hollingdean, Brighton, run by Veolia. This MRF does not take the recycled waste collected in Rother DC – that gets sent to Crayford in Kent, which is run by Viridor and collects slightly different types of material. Disappointingly, though, the facility in Crayford is not set up for visits by members of the public.

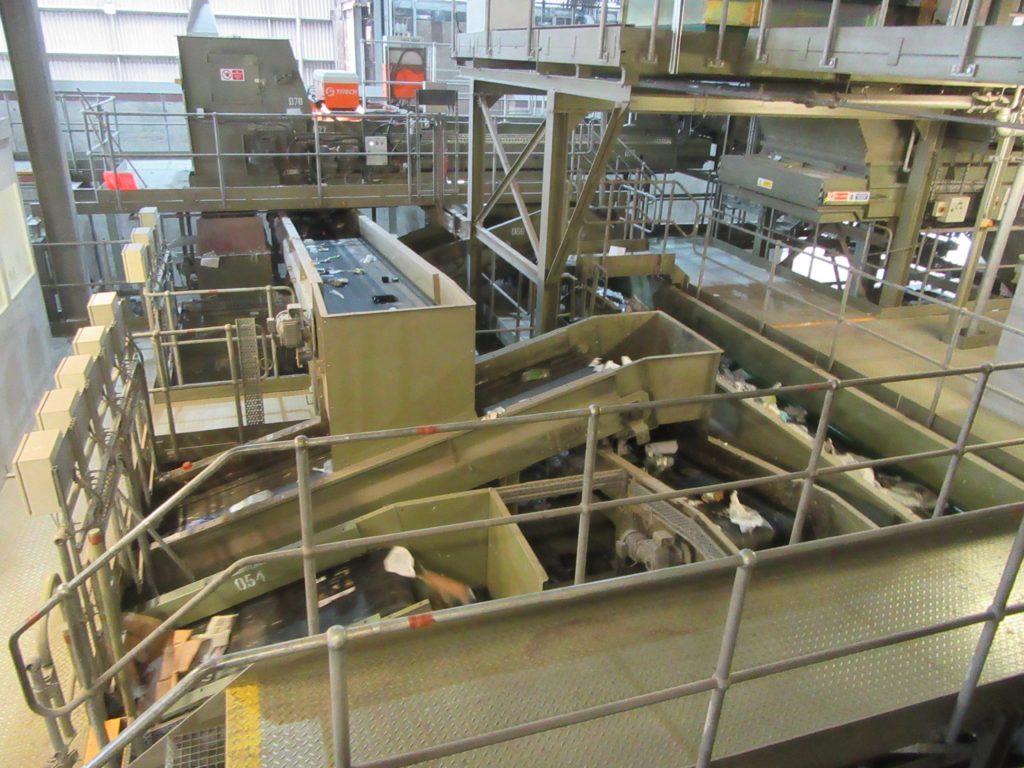

The MRF in Hollingdean was built in 2009 and serves Brighton & Hove as well as other parts of East Sussex. The purpose of the facility is to separate recyclable waste, but unlike the facility in Crayford, does not take glass or Tetrapaks. It covers a throughput of 160,000 tonnes a year to cope with this but could deal with up to double this figure if the demand were there. The equipment in both Crayford and Hollingdean is similar though and the technology has not changed much in the past 10 years.

The recyclable waste arrives by truck from waste transfer stations or directly from local authority collections. All other waste from our black bins, referred to as residual waste, gets sent to the Newhaven Energy Recovery Centre (ERF) to get incinerated, generating electricity to supply the National Grid.

The recyclable waste first goes into a bag splitter, which removes most of the black bags, from there it goes up a conveyor into a pre-sort cabin. One of the most surprising aspects of the visit is how essential sorting by humans is to the process. Two operatives separate out items which should not be there, known as contaminate. This includes polystyrene, glass, plastic pots, tubs and trays and many other items. Amongst the most dangerous contaminates are hypodermic needles, which risk piercing gloves.

Some heavy items could damage the equipment, such as brake discs, rubble or pieces of pipe. Glitter, VHS tape and fairy lights are also a nuisance to the process. Communal bins in particular can be a major source of contaminate. The operatives can slow down or even stop the belt if needed.

After this, the conveyor continues into a trommel, which separates out much of the paper and cardboard. So-called air knives are also used further along the process to further collect paper. This goes into a paper cabin, again a staffed area, with cardboard manually separated from mixed paper.

After the trommel, the conveyor continues to a disc screen, which separates off much of the remaining contaminate. Interestingly, any object smaller than 40mm across is deemed contaminate, so that includes any loose metal or plastic bottle tops! The conveyor then passes along a magnet which separates out all ferrous metal.

An eddy current separator is used to draw aluminium cans and other non-ferrous metals. There is then a plastic optical sorter, used to identify different materials and colours. The non-ferrous metal and plastic then goes into another cabin to be sorted by hand. Any remaining items on the main conveyor go through an optical sorter for paper, again separating out any contaminate.

Of all the material brought to the facility, 15% is contaminate which goes to the ERF, all other materials are baled and then sold on to other facilities to further process and clean.

There is lots of sampling – four times a day – to ensure that the material is high quality, so as to get the best sale price. Steel is often sent to Port Talbot, aluminium to Warrington, to be used for cans or car parts, plastics goes on to other facilities, in particular to Veolia’s Plastic Recycling Facility in Rainham, Essex. Paper and cardboard is mostly sent to Kemsley Mill in Kent – the paper mill in Aylesford closed down a number of years ago. Cardboard often goes back to China, which makes some sense given that so much of what we consume here is manufactured and packaged there.

Many of us were interested in plastic, as the correct disposal of this is known to be confusing to many. The non-recyclability of many plastics is a major problem. Currently about one third of plastics are easily recyclable (such as PET used for drink bottles or HDPE used for milk or shampoo bottles), one third is possible but difficult (such as LDPE for plastic bags) and the remainder is virtually not recyclable (such as polypropylene drink cups or polystyrene).

Veolia is increasingly opening new plants that can process specific plastics, for instance HDPE in Dagenham, with a new plant to process PET opening soon too. There is an increasing change in mindset about how we use and dispose of plastic, again in no small measure thanks to David Attenborough.

Veolia for instance advocates the introduction of deposit return schemes. Many large UK companies, including Veolia and Viridor, are now also part of the UK Plastics Pact, which aims by 2025 to:

• Make 100% of plastic packaging re-usable, recyclable or compostable.

• See 70% of plastic packaging effectively recycled or composted.

• Take action to eliminate problematic or unnecessary single-use packaging items through redesign, innovation or alternative (reuse) delivery models.

• Achieve 30% average recycled content across all plastic packaging.

These are laudable targets and every effort needs to be made to achieve them. Preferably there would be new legislation to enforce action. Currently huge amounts of packaging waste is still being sent overseas on the basis that it will be recycled and turned into new products, when in practice, much of it is being dumped in sites from Turkey to Malaysia.

Improving our infrastructure to allow the UK to recycle its own plastic waste is paramount.

Overall, our group was at least reassured that when we put recyclable waste into our green bins, much of it is indeed recycled. Of concern is that recycling rates have stagnated at about 44% in the UK overall and the UK is unlikely to hit its target of 50% by 2020. The MRF in Hollingdean has seen a decrease in the quality of the material brought in, this is probably due to lack of funding for local authorities to inform and educate its citizens.

REG is disappointed that Rother DC’s contract with Kier, recently replaced by Biffa, allows for glass to be mixed in with other recyclables. It is highly contaminated when mixed in, damages the plant and degrades all the baled material. Also, it cannot be re-used as glass, but gets used for making road aggregate or insulation. We would want to see this aspect of the contract reversed, so that it can again be collected separately. Ideally, glass bottles should be reused in deposit return schemes.

Finally, as I am often asked this question: how much rinsing is needed for metal and plastic? A quick rinse is enough, as there are further cleaning processes in the system.

REG wishes to thank the manager, Steve Usher for his time and patience for all our questions.

Image Credits: Dominic Manning .